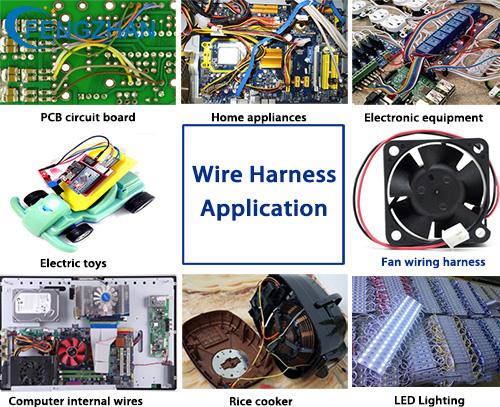

Place of Origin: Guangdong, China

Application:Electronic, LED Display, Medical Device

Length: 100mm/150mm/200mm or custom

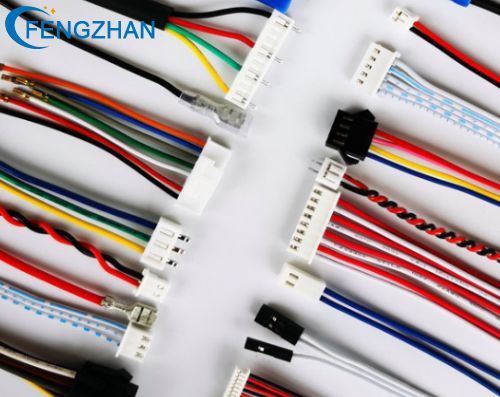

Connector: SH,PH, ZH, VH, SM, SYP etc...

Pins: 2pin-12pin(customized)

Pitch: 0.5/0.8/1.0/1.25/1.27/2.0mm/2.54mm

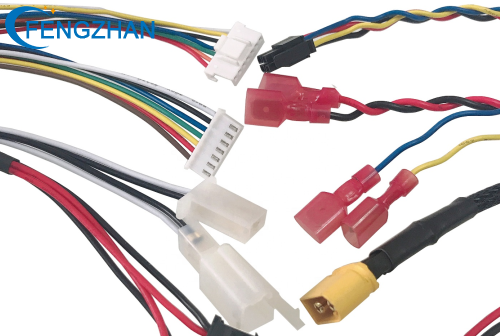

Wire Gauge: 10-30AWG

Wire Material: PVC, Silicon

1. Wiring Harness color separation

Insulated cores should be separated by colors that are easy to identify and not easy to erase, and should comply with the requirements for marking methods for wires and cables. When necessary, other identification methods are allowed, but they should be specified in the product standard. The preferred colors and color sequence are as follows:

a) Single-core cable: no preferred color;

b) Two-core cable: no preferred color;

c) Three-core cable: green/yellow double color, light blue, brown; or light blue, black, brown;

d) Four-core cable: green/yellow double color, light blue, black, brown; or light blue, black, brown, black or brown;

e) Five-core cable: green/yellow bicolor, light blue, black, brown, black or brown; or light blue, black, brown, black or brown, black or brown.

f) The green/yellow color is the color of the grounding wire core. When there is a green/yellow grounding wire in the insulated wire of the cable, the other insulated wire cores are not allowed to be green or yellow.

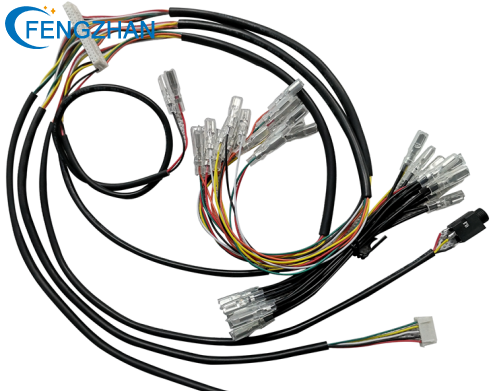

2. Cable Harness Mechanical strength

The crimping terminal part should be able to withstand the mechanical stress that may occur during normal use. Whether it is qualified or not, it may be checked by the following tensile strength test.

a) Apply the specified pulling force for 1 min. When applying force, explosive force should not be used. This tensile force can also be applied by a tensile testing machine. The moving speed of the head of the testing machine should be between 25mm (1.0in)/min and 50mm (2.0in)/min, and there should be no falling off or breaking.

b) The wire should be subjected to a burning test. After the test, the flame on the surface of the sample should be extinguished by itself, and the distance between the affected part of its scorch and the lower edge of the upper clamp of the test device should not be less than 50mm.

c) The wire should be able to withstand the specified AC 50Hz non-immersion voltage test, and the insulated cores of two-core and above round sheathed wires should withstand the specified AC 50Hz non-immersion voltage test.

3. Electrical Wire Cross-sectional area

The preferred cross-sectional area of the wire should be 0.5mm2, 0.75mm2, 1.0mm2, 1.5mm2, 2.5mm2, 4.0mm2 and 6.0mm2, or the corresponding AWG wire gauge.

4. The electrical strength of the hook up wire

The voltage is applied in sequence between all the other conductors connected to each wire pair, and then the voltage is applied between all the connected conductors and the sheath:

a) Weak Wire Harness: 1500V AC voltage for 1min;

b) Strong wire harness: 2000V AC voltage for 1min;

c) Sheath: 3750V AC voltage for 1min

Contact: Lynn Long

Phone: 0086 13640200141

E-mail: lynn@fzwires.com

Whatsapp:0086 13640200141

Add: No. 19, Minye Street, Zhufoling Community, Tangxia Town, Dongguan City, China