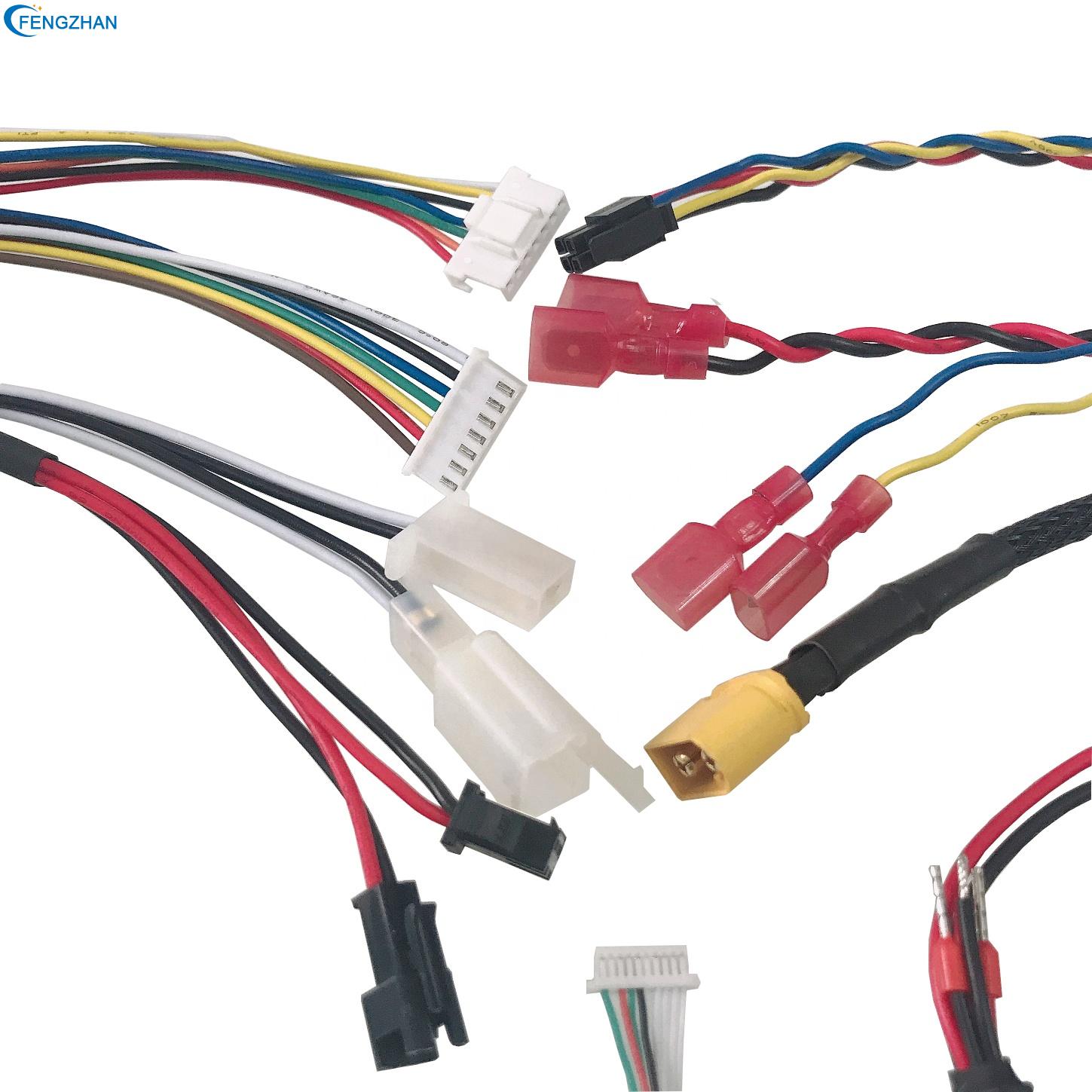

During the Wire Harness processing and production process, what are the requirements for cable harness? Today I will briefly introduce to you as follows:

1. Requirements for cutting and stripping: the cutting surface is flat and the copper wire is neat; all stripping heads (mouths) must not cut the copper wire; the copper wire at the stripping head must not be disordered, and pay attention to the wire take-up operation.

2. Opening size requirements: The basic size when opening should meet the design requirements; the limit deviation of the opening size changes with the basic size (L=opening size unit: mm): L<300, the deviation is 0+ 2;300≤L<1000, the deviation is 0+5;1000≤L<4000, the deviation is 0+10;L>4000, the deviation is 0+15

3. Operating specifications for the auxiliary process of cable harness opening: after the heat shrink tube is baked and shrunk, it should be ensured that: there is no movement along the axial direction of the wire; there is no leakage of copper wire when observed along the radial direction of the wire; for hole-type and fork-type joints, heat The shrink tube does not interfere with the outer edge contour of the joint.

4. Operating specifications for the crimping process: The terminals should be pressed tightly on the conductor and the sealing plug respectively. The sealing plug should not be damaged during crimping. There should be no visible space between the conductor and the sealing plug and between the sealing plug and the sheath. clearance; if using soldering method, corrosive solder paste is not allowed. The solder joints must be smooth, and no leakage, incomplete penetration, or impurities are allowed; the cross-sections of terminals and wires crimped using the crimping method should meet the requirements of Table-1.

5. Operation specifications for the wire merging process: In the production of wires, wires with the same function are often merged. The merging methods are divided into two types: copper strip crimping and soldering. They should meet the following requirements: Use the crimping method. When using, the conductor should not be broken by pressure, and the contacts should meet the requirements in the table below; when using the soldering method, corrosive solder paste is not allowed, the solder joints must be smooth, and no leakage, incomplete soldering, or impurities are allowed; the contacts should be firm, It should not be damaged or detached under the specified tensile force, and its tensile force value should not be less than the requirements in the above table.

Fengzhan Electronics specializes in manufacturing wire harnesses and cable assemblies, contact us for more information. Email: lynn@fzwires.com

Contact: Lynn Long

Phone: 0086 13640200141

E-mail: lynn@fzwires.com

Whatsapp:0086 13640200141

Add: No. 19, Minye Street, Zhufoling Community, Tangxia Town, Dongguan City, China