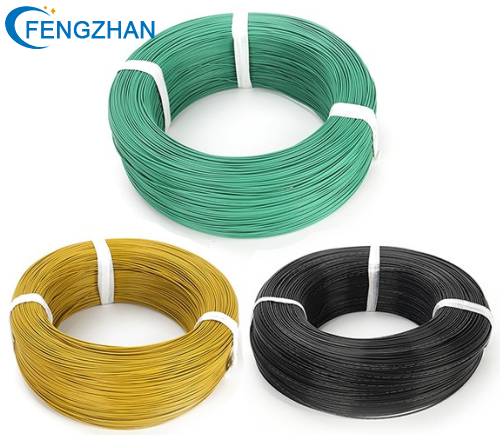

Teflon wire is a wire made of PTFE, commonly known as fluoroplastics, as insulation and wrapped with metal conductors.

Because Teflon has: non-stickiness, heat resistance, sliding properties, moisture resistance, abrasion resistance, corrosion resistance and other characteristics. Therefore, compared with other high-temperature wires, Teflon wire has excellent thermal stability and mechanical abrasion resistance, electrical insulation properties, resistance to strong acids and alkalis, corrosion resistance, fire resistance and non-combustibility, high oxygen index, low smoke and halogen free, no aging, easy to strip. , High strength and resistance to friction. There is a certain difference between the temperature resistance of the Teflon wire and the material of the outsourcing material.

There are roughly three types of PTFE as follows:

1. PTFE (polytetrafluoroethylene) non-stick coating can be used continuously at 260°C, with a maximum use temperature of 290-300°C, extremely low friction coefficient, good wear resistance and excellent chemical stability.

2. FEP: FEP (fluorinated ethylene propylene copolymer) non-stick coating melts and flows to form a non-porous film during baking. It has excellent chemical stability and excellent non-stick characteristics. The maximum use temperature is 200 ℃.

3. PFA: PFA (perfluoroalkyl compound) non-stick coating, like FEP, melts and flows during baking to form a non-porous film. The advantage of PFA is that it has a higher continuous use temperature of 260°C, stronger stiffness and toughness, and is especially suitable for anti-sticking and chemical resistance applications under high temperature conditions.

Contact: Lynn Long

Phone: 0086 13640200141

E-mail: lynn@fzwires.com

Whatsapp:0086 13640200141

Add: No. 19, Minye Street, Zhufoling Community, Tangxia Town, Dongguan City, China