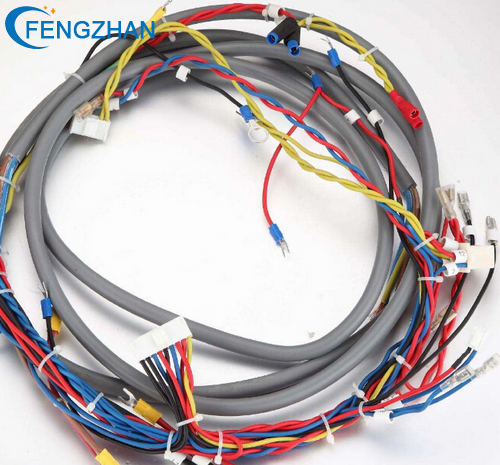

In a complete set of wiring harnesses, there are generally more than a thousand parts, and the cable tie is one of the most inconspicuous parts among the thousand.

Regarding automotive wiring harness ties, many people inevitably think that this small product is not worth talking about. Some people even think that the integration of electronic products is becoming more and more advanced, and wiring harness ties are dispensable. This view is inevitably biased. In fact, in developed countries such as Europe, America and Japan, there are many large enterprises specializing in the production and research and development of various Wire Harness ties.

Although the wire tie product is small, its importance cannot be ignored. The main function of the wire tie is to integrate, fix and arrange the wire harness. The quality of the cable tie is not good, and it loosens or breaks during use. In the slightest, the wiring harness is entangled, which affects the appearance and product image. Therefore, companies that attach importance to product quality tend to be very rigorous in the selection of wire ties.

1. Material selection

When selecting a wire tie, first consider its application, mainly temperature, light and other factors. General cable tie companies use nylon as the raw material for wire ties, which has the characteristics of large applicable temperature range and corrosion resistance. Nylon ties have the characteristics of fast tying, good insulation, self-selling and fastness, and convenient use. They are in production. Different ingredients are added in the process to make the product suitable for different occasions. In places where the temperature of the car is not high, such as inside the car, we can choose a general cable tie of -40-85 degrees. However, in the engine compartment, there is a certain temperature requirement for the cable tie of the wire harness. Generally, we choose the cable tie of -40---105 degrees. At this time, we need to add heat-resistant materials.

2. Determination of the lowest tensile strength

The lowest tensile strength is the key to choosing a tie, because it reflects the maximum load that the tie can withstand.

The inspection of tie tools is not as simple as it seems. It is very important to comply with the standard testing procedures and keep the testing conditions consistent, such as the size, cross-sectional area and water content of the tie. If you use unused cable ties and/or different test conditions, it is easy to produce two different test results.

The test procedure for the minimum tensile strength of the cable tie is to test the minimum grip strength.

1. Use the matching application tool to fix the cable tie on a breakable mandrel test sensor.

2. The speed set by the spindle opens in opposite directions.

3. The maximum load can be determined when the cable tie is disconnected

Generally, the cutting speed, the position of the tool and the tie, the wear of the tool wear parts and the state of the tie all play an important role in determining the tensile strength of the state. Therefore, we must point out that the data we provide can only be used as guide values for our reference.

These data cannot simply be copied into practice. If the tension value must be recorded or meet the specification, we recommend using a tension meter to adjust the tool. In principle, half of the minimum holding force of the cable tie should be used as the tensile strength.

The minimum tensile strength (also referred to as the minimum unlocking force) is the minimum force that the cable tie can withstand before it is damaged. Threaded ties can be used to determine the magnitude of this force. Please use the following formula to calculate the correct tensile strength of the tool.

3. Choice of form

Most of the fixing in the wire harness is done with a cable tie. The role of the cable tie is to strengthen the wire harness and secure it firmly and reliably to the body sheet metal holes, bolts, steel plates and other parts.

Although wiring harness ties are accessory products, they usually do not account for a large proportion of the entire product. To put it bluntly, a cable tie is not valuable, but its quality will greatly affect the overall quality of the wiring harness. Therefore, when we choose cable ties, we should fully consider various factors and carefully choose applicable products.

Contact: Lynn Long

Phone: 0086 13640200141

E-mail: lynn@fzwires.com

Whatsapp:0086 13640200141

Add: No. 19, Minye Street, Zhufoling Community, Tangxia Town, Dongguan City, China