As one of the leading custom wire harness manufacturers and suppliers in China, we warmly welcome you to wholesale cheap custom wire harness from our factory. All customized products are with high quality and low price. Contact us for free sample.

Custom Wire Harness Manufacturer

- 10 years of experience as a factory specializing in the manufacture of wire and cable harnesses.

- Provide customized services and solutions, fast quotes according to customer requirements.

- Professional team and strict control production process, high quality and fast delivery are our advantages.

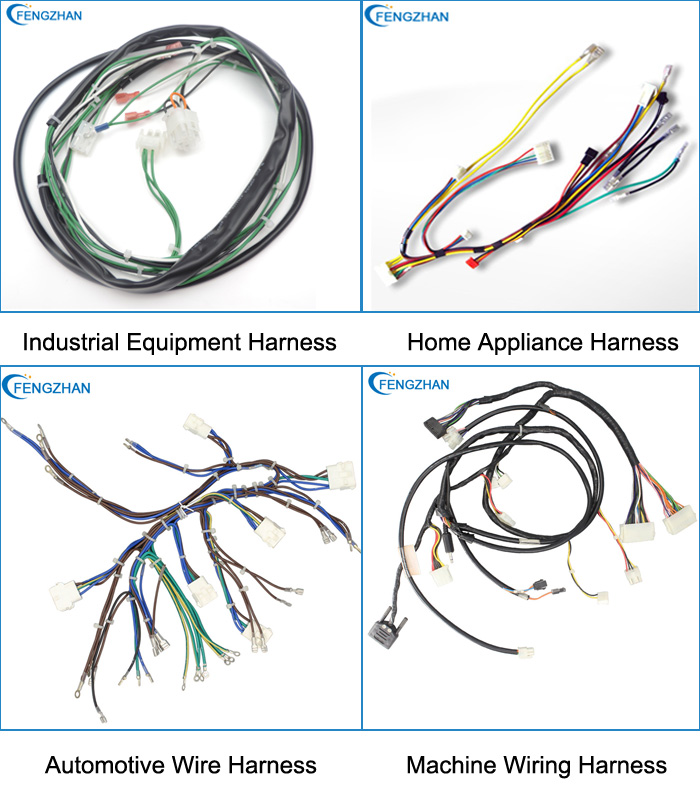

Fields of application of Custom Wire Harness

1. Industrial equipment: grinding machines, drilling machines, CNC machine tools, lathes, lifting equipment, automated assembly wires, etc.

2. Automobile manufacturing:engine, instrument panel, door, battery, car audio and video, light wire, etc.

3. Office intelligence: printers, copiers, scanners, computers, monitoring, access control, attendance, etc.;

4. Financial equipment: ATM machines, number machines, cash registers, terminals, etc.

5. Medical equipment: ventilator, heart rate monitor, monitor, anesthesia machine, digital ultrasound machine, blood/biochemical analyzer, radiological imaging equipment, etc.

6. Household appliances: refrigerators, air conditioners, TVs, washing machines, water heaters, wine refrigerators, stereos, VCDs, etc.

The following are the materials for the wire harness selection.

1. Material selection of terminals

The copper used for terminal materials (copper parts) is mainly brass and bronze (the hardness of brass is slightly lower than that of bronze), and brass accounts for a larger proportion. In addition, different coatings can be selected according to different needs.

2, the choice of connector

The commonly used materials for connector (plastic parts) are mainly PA6, PA66, ABS, PBT, pp, etc. According to the actual situation, flame retardant or reinforcing materials can be added to the plastic to achieve the purpose of reinforcement or flame retardant, such as adding glass fiber reinforcement.

3. Selection of wire harness wires

Depending on the application environment, select the corresponding wire material.

4, the choice of dressing materials

Wire harness wrapping plays the role of wear resistance, flame retardant, anti-corrosion, preventing disturbance, reducing noise, and beautifying the appearance. Generally, the wrapping material is selected according to the working environment and the size of the space. In the selection of dressing materials, there are generally tapes, corrugated pipes, PVC pipes, etc.

Components of the Custom Wire Harness

Wire Harness are mainly composed of wires + connectors + terminals. In addition, some wiring harnesses will have accessories such as protective covers, brackets, jackets, fuse boxes (fuses and relays) and heat shrink tubing.

- Connector pitch classification: 0.8mm, 1.0mm, 1.20mm, 1.25mm, 1.27mm, 1.5mm, 2.0mm, 2.54mm, 3.00mm, 3.96mm, 4.2mm, 4.8mm, 6.3mm, etc.

- Connector type classification: XH, PH, CH, ZH, VH, L6.2, SM, 5557, 5559, 2.8, 4.8, 6.3 spring inserts, Y-type terminals, U-type terminals and various automotive connectors, etc.

- Connector brand classification: JST, MOLEX, HRS, TE, AMP, etc.

- Wire classification: UL1007, UL1015, UL1430, UL2468, UL1061, UL3239, UL2464 UL2651, VDE Wire, sheathed wire, shielded wire, electronic wire, etc.

Product Feature

- The products have passed the certification of UL/CSA in the United States and Canada;

- The products have passed ROHS, REACH environmental protection certification;

Production Process

1. Pipe cutting: cutting according to the size of the corrugated pipe, PVC pipe, glass fiber pipe process card.

2. Thread cutting/crimping: according to the size of the cutting process card, tangent and terminal crimping (automatic and semi-automatic).

3. Connector: put the terminals into the corresponding connector according to the color order

4. Heat shrink: According to the process document, put the heat shrink tube on the wire harness and heat it to shrink it.

5. Stranded wire: twist the relevant wires according to the requirements of the process card.

6. Welding: Weld the relevant wires according to the requirements of the process card.

7. Assembly: hang the wires on the wiring board and install the sheath according to the process requirements; wrap the wires with tape and install corrugated pipes, PVC pipes, tapes, cable ties, clips and other accessories outside the wire harness as required.

8. Electrical test: Check whether the wiring harness has faults such as wrong circuit, short circuit, open circuit, etc., to ensure that the electrical performance of the wiring harness is good.

9. Appearance inspection: Check whether all parts of the harness branch, appearance, etc. meet the requirements.

10. Finished product packaging: packaging qualified finished products.

Custom new wire and cable harness? Request a quote now!

Email: lynn@fzwires.com

Phone/WhatsApp: +86 13640200141

Contact: Lynn Long

Phone: 0086 13640200141

E-mail: lynn@fzwires.com

Whatsapp:0086 13640200141

Add: No. 19, Minye Street, Zhufoling Community, Tangxia Town, Dongguan City, China