The vast majority of wire and cable products are products with exactly the same cross-section (cross-section) shape (ignoring the errors caused by manufacturing) and elongated products. This is because they are used as a feature of a circuit or a coil in a system or equipment. Therefore, to study and analyze the structure of cable products, only need to observe and analyze from its cross section.

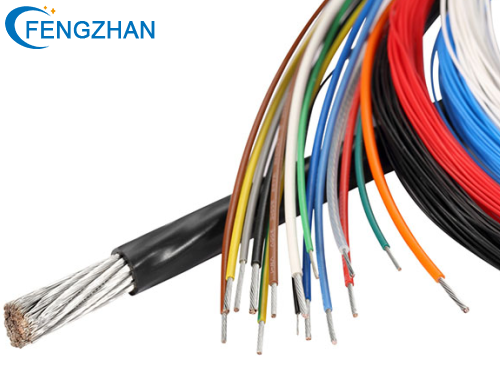

The structural elements of wire and cable products can generally be divided into four main structural components: wire, insulation layer, shielding and protective layer, as well as filling elements and tensile elements. According to the use requirements and application occasions of the product, some product structures are extremely simple.

1. Cable material

In a sense, the wire and cable manufacturing industry is a material finishing and assembly industry. First, the amount of materials used is huge, and the cost of materials in cable products accounts for 80-90% of the total manufacturing cost; Second, the types and varieties of materials used are very large, and the performance requirements are particularly high. For example, copper is required for copper purity. Above 99.95%, some products use oxygen-free high-purity copper; third, the selection of materials will have a decisive impact on the manufacturing process, product performance and service life. At the same time, the benefits of wire and cable manufacturing enterprises are also closely related to whether materials can be scientifically saved in the selection, processing and production management of materials.

Therefore, the design of wire and cable products must be carried out at the same time as the selection of materials. Generally, several materials are selected and determined after the process and performance screening tests.

The materials for cable products can be divided into conductive materials, insulating materials, filling materials, shielding materials, and protective layer materials according to their use parts and functions. But some of these materials are common to several structural parts. Especially thermoplastic materials, such as polyvinyl chloride, polyethylene, etc., can be used on insulation or sheaths as long as part of the formulation is changed. The materials used in the manufacture of cable products involve a wide range of categories, and there are particularly many varieties and specifications (brands).

2. The name and material of the product structure

(1) Wire: The most basic and essential component for the product to carry out electric current or electromagnetic wave information transmission function.

Main material: Conductor is the abbreviation of conductive core, made of copper, aluminum, copper-clad steel, copper-clad aluminum and other non-ferrous metals with excellent conductivity, and optical fiber is used as the conductor.

There are bare copper wire, tinned wire; single branch wire, stranded wire; tinned wire after twisting.

(2) Insulation layer: It is a component that is wrapped around the periphery of the wire and plays an electrical insulation role. That is to say, it can ensure that the transmitted current, electromagnetic waves, and light waves only travel along the wires and do not flow to the outside. The potential on the conductor (ie the potential difference formed to the surrounding objects, that is, the voltage) can be isolated, that is, it is necessary to ensure the normal transmission of the wire Function, but also to ensure the safety of external objects and people. Wire and insulation are the two basic components that must be equipped to form cable products (except bare wires).

Main materials: PVC, PE, XLPE, polypropylene PP, fluorine plastic F, rubber

(3) Filling structure: Many wire and cable products are multi-core. After these insulated cores or pairs are cabled (or grouped into multiple cables), one is that the shape is not round, and the other is that there is a gap between the insulated cores. There is a large gap, so a filling structure must be added when the cable is formed. The filling structure is to make the outer diameter of the cable relatively round in order to facilitate the wrapping and squeezing of the sheath.

Main material: PP rope

(4) Shield: It is a component that isolates the electromagnetic field in the cable product from the external electromagnetic field; some cable products also need to be isolated from each other between different wire pairs (or wire groups) inside. It can be said that the shielding layer is a kind of "electromagnetic isolation screen". The conductor shielding and insulation shielding of high-voltage cables are used to homogenize the electric field distribution.

Main materials: bare copper wire, copper clad steel wire, tinned copper wire

(5) Protective layer: When wire and cable products are installed and operated in various environments, they must have a component that protects the entire product, especially the insulating layer, which is the protective layer.

Because insulating materials are required to have excellent various electrical insulation properties, they must require extremely high purity and minimal impurity content; often they cannot take into account their ability to protect the outside world. Therefore, for the outside world (ie installation, use occasions and ) The endurance or resistance of various mechanical forces, resistance to atmospheric environment, resistance to chemicals or oils, prevention of biological damage, and reduction of fire hazards must be borne by various protective layer structures.

Main materials: PVC, PE, rubber, aluminum, steel belt

Contact: Lynn Long

Phone: 0086 13640200141

E-mail: lynn@fzwires.com

Whatsapp:0086 13640200141

Add: No. 19, Minye Street, Zhufoling Community, Tangxia Town, Dongguan City, China